The Galaxy Z TriFold is Samsung’s top-dog foldable, and it arrives as a remarkable engineering feat for the brand. We already covered some bits in our announcement coverage, but Samsung shared an official video that details the assembly and rigorous testing process that ensures each Z TriFold will perform reliably in daily use.

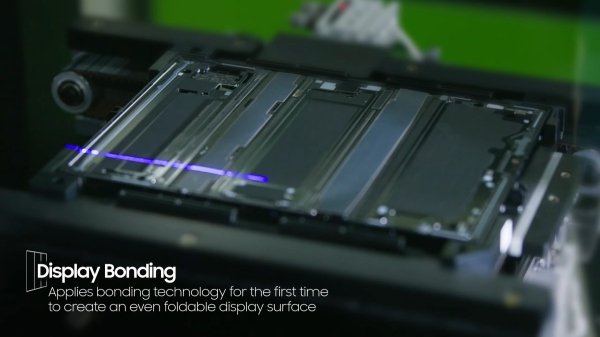

Samsung claims it is leveraging a decade of foldable smartphone innovation, and it all starts with the titanium hinge assembly, which incorporates two Armor FlexHinges. Samsung uses an automated assembly system and also incorporates 3D laser scanning for quality control of the main display.

Samsung is also implementing a 200,000-cycle folding test to ensure the main display can withstand the test of 100 folds per day for five years.

The Z TriFold even undergoes a high-speed CT test, which analyzes key internal structure components like the flexible printed circuit board to ensure all requirements are met. From there, the foldable takes on a camera sharpness test, which makes sure its cameras are all ready to go.

Samsung is also doing what it calls a “real-world scenario test” which simulates active use cases across a wide range of conditions, including network, battery, display and environmental factors.

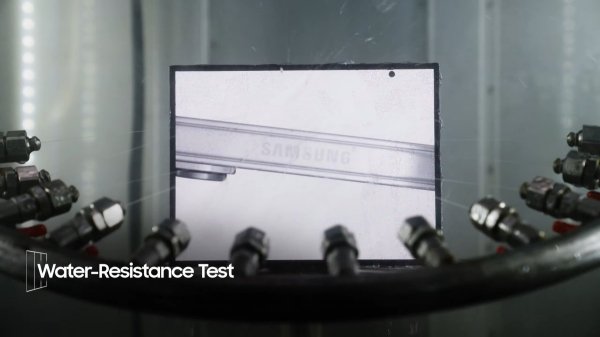

Last but not least, Samsung makes sure to test out the Z TriFold’s IPX8 water resistance by spraying the device with water jets from various angles.